Al Mana Precision

Al Mana Precision Industries, is a member of M.H Al Mana Group of companies located at New Industrial Area, a leading manufacturer of Fire Rated and Non-Fire Rated solid Single, Double, Fully glazed doors, Windows, Cabinets, Kahramaa Door, Fire Rated Hardwares and Fire Rated Glass.

Al Mana Precision Industries is a reliable Fire Door manufacturer in Qatar region by using high quality materials, latest technology facility and machineries equipped with well-trained and qualified personnel.

We have a reputation of consistent quality combined with high level of services and looking after the safety of each employee. Our accredited engineers and production team have the expertise, knowledge and wide experiences to assist our valued clients in achieving their targeted goals on any project no matter the size and demands. We value excellence in both our products and in our deliverances. Our team works diligently and attentively keen on every stage of the process, following the standard operational procedures and deal with every customer requirement with the utmost importance.

We highly value our customer and pledge to establish long-term business relationship by partnering with them through- out the development from concept and design. Our goal is to provide personal attention, understanding our customer’s need and earning their trust by exceeding their expectations through exceptional performance by every member of our team.

Our products are tested and certified by Third-party certification such as IFC and Exova.

VISION

- To be the leading manufacturer of fire safety solution in all industries, sustaining a competitive advantage through best product and services with a total quality commitment and a strong customer focus.

MISSION

- To exceed client expectations by maintaining high-quality of products and services using comprehensiveness of the services. Our Company's product offer was created for the customer's needs, within the existing product groups and offers superior long-term service solutions.

Manufacturing Technology

Al Mana Precision Industries production depart- ment uses the best facilities and latest technology of machines such as CNC Punching machine, Hydraulic shearing, bending, powder coating and wood finish machines. Allowing us to create the most innovative manufacturing solutions availa- ble to suits every client requirements and take the production to the next level.

Product Line

Al Mana offers a wide range of doors with varying fire rating, sizes, materials. and comprehensive line of Single and Double-Leaf Doors.

Al Mana Fire Doors

- Galvanized Steel Doors

- Stainless Steel Doors

- Glazed Doors

- Honeycomb Core

- Rockwool Core

- Powder Coated

- Wood Finished

- Mirror/Hairline Finish (for Stainless Steel Only)

- Vision Lite and Panels

- Louvers

- Smoke Proofing

- Fire-rating 60 up to 180 minutes

Al Mana fire engineering also manufactures specialty doors such as Acoustic Doors, Lead-Lined Doors, Sliding Doors,and Folding Doors, as well as frames Windows.

Fire Rated Doors

Approved Fire-Rating and Dimensions for Al Mana Fire Doors (Leaf Thickness: 45mm, Leaf Sheet Thickness: 1.2mm).

Gulf Concrete Products

Gulf Concrete Products is a member of Almana group of companies. GCP prestressed concerete is a specialist manufacturer and supplier of prestressed concrete products. The company, which is based in Doha, Qatar, was established in the end of 1995.

GCP structural concrete flooring systems have been developed by Doha Qatar Engineers to satisfy the requirements of Doha Qatar construction industry and associated design codes. The GCP Product range offers economic solutions to all normal load, span and soffit requirements.

The company has a policy of on-going product development to match the constantly chnaging demands of a competitive building industry.

GCP Prestressed concrete welcomes enquiries on both standard and other specialised products.

Oil & Gas Technology W.L.L.

MAIN SERVICES OF THE COMPANY

As painting / scaffolding contractor with his highly skilled and experienced workforce, backup by well-maintained plant and equipment have completed number of contracts in onshore. The work requires a high standard of safety, fundamental and total adherence to the client schedule and we have track record of completion of the work within time frame and in accordance with the specifications at all times. Long list of satisfied clients is an indication to our relenting endeavors to meet the organization objectives and for customer satisfaction.

Star Line Block Factory

Our Products are patently designed and manufactured in precise compliance.

With the said norms and specifications in order that the product may last long as well as carry the aesthetic attraction.

Scope of activities

- Manufacturer of Concrete Products in assorted color, shapes and thicknesses.

- Supply of the manufactured Goods to the Qatar Market as well as buyers in the neighboring countries and overseas countries.

- Fixing work on subcontract and / or turnkey basis.

Orientation

We are one of the leading manufacturers of concrete products in assorted colors, shapes and thicknesses in Qatar. The full generations.

Our Products are regularly tested for compressive strength, water absorption, abrasion resistance, Tension strength and color lasting by recognized laboratories in accordance with the international specifications. We receive positive test results from the testing laboratories.

We pleased to inform you that the quality of our management system products and services have been assessed and found to be in accordance with the requirement of quality standard and also we are totally complying to the environmental management system for manufacturing of tiles and blocks.

We normally allow visits to our factory from business partners, friends and well-wishers with or with out prior invitation.

Block Ingredients

The following ingredients are used to in the manufacture of our blocks.

- Crushed concretes 0mm to 10mm.

- Potable water, free from all chemicals.

- Ordinary Portland and Moderate Sulphate Resisting Cement (type2) OR Sulphate Resisting Portland Cement. (as required by the client).

Methods of Productions

The manufacture of procedure of the block is 3 stage processes viz. Mixing, Pressing and Curing.

Mixing

The mixing plant guided by computer mixes aggregates, cement and water proportioned ratios:

- Crushed Concrete 0mm to 10mm.

- Potable water, free from all chemicals.

- Ordinary Portland and Moderate Sulphate Resisting Cement (type2) OR Sulphate Resisting Portland Cement. (as required by the client).

- Cement Content is 360kg /m³

To begin with Crushed Concrete 0mm to 10mm is transferred from outer hoppers to inner hopper where potable water and cement are mixed. As soon as the process is complete, the mix content is then transferred to press machine where systematic process of filling vibration pressing takes place.

The blocks obtained from either of the systems equally yield strength not less than 7N/mm². The products obtained are of high quality. Tests conducted on products give identical results with respect of strength and water absorption. The outer surface of the products is non-slip and yield smooth finish.

Curing

When the pressing process is complete, the tiles are then stacked in steel pallets and transferred to curing chambers and stacked on shelves. The shelves are kept at a distance of 20 cm from each other’s. Later the chamber is immediately closed and heating system is set on. The temperature is slowly raised to reach up to 60 degree Celsius with humidity up to 100% the curing lasts for at least 14 days.

Packing

The company had, time and again gone to strenuous efforts in the past in order to improve the existing packing system.

At present the blocks are bundled by means of rust proof steel strapping being the latest strapping system available in the international market.

Quality Control

- Blocks producers are in accordance with BS Standards.

- All Blocks are automatically cured in Autoclaved Chambers.

- All Raw Materials are supplied from government certified Suppliers.

Laboratory Quality Control

Starline Do Make Third Party Laboratory tests on accordance with any Standards required by the End user. Yet, Starline do have quality control material testing reports to maintain quality control system.

Third Party Lab

Two Labs are certified that do the third party testing.

- Al- Tayseer Laboratories P.O Box 1556 Doha Qatar.

- Lab Tech Laboratories P.O Box 39019 Doha Qatar.

Our Products

1. 8” Hollow and Solid Block.

2. 6” Hollow and Solid Block.

3. 4” Hollow and Solid Block.

4. Interlock (All Shape and Colors).

5. Hurdy Blocks.

Capacity

Our Daily Products are,

- 52,000 Blocks of 8” Blocks.

- 80,000 Blocks of 6” Blocks.

- 98,000 Blocks of 4” Blocks.

- 3000 Meter Squared.

Raw Material Sources

Cement : Qatar Cement Company.

Aggregate : Qatar Quarry.

Sand : Government Sand Quarry in Um Saed.

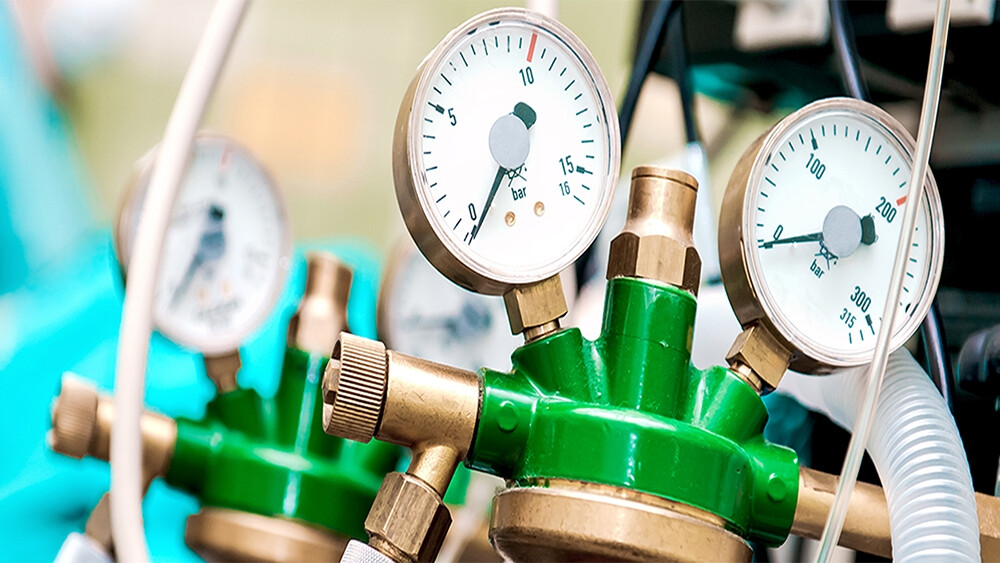

National Industrial Gas Plants

National Industrial Gas Plants is a member of Mohammed Hamad Al-Mana Goup of Companies, which was established in the year 1952 by its visionary founder Mr. Mohd. Hamad Almana. Our plant is situated at street No. 45, Salwa Industrial Area. All the Industrial Gases like Oxygen, Nitrogen, Argon, Carbon Dioxide, Breathing Air, Acetylene, Nitrous Oxide, Hydrogen, Mixture Gases and Calibration Gases are manufactured under one roof. Our strength and capabilities are further extended by our sister concerns at UAE, Saudi Arabia, Egypt and Sudan.

Commitment to quality, competitive prices, environment protection, customer satisfaction and safety at large have made us leaders in this vital sector. Oil and gas have played a major roll in influencing our expansion with the latest state-of the-art technological plants to meet the market’s demand for products and services. We have an extensive welding and safety products departments to cater for the customer requirements.

The company is managed by a team of experts who have vast experience in the process and services of industrial gases. We are accredited with ISO 9001:2000, ISO 14001:1996, and we are working for ISO 18001:1999 OHSAS. We have bulk storage facility and fleet of transport, and our dedicated round-the-clock service could be availed at any time. For more information, visit our website: www.mhalmanagroup.com

Qatar is booming and is making great strides in all aspects of progress. Our sincere thanks and appreciation goes to our visionary leader His Highness Sheikh Hamad Bin Khalifa Al Thani, The Emir of Qatar. We also take great pride in working for the progress and prosperity of our country.

OUR PRODUCTS (LIQUID)

- Liquid Nitrogen

- Liquid Oxygen

- Liquid Argon

- Liquid Carbondioxide

- Liquid Helium

- Liquid Propylene

OUR PRODUCTS (GASES)

- Oxygen (Medical and Industrial) purity 99.7%

- Nitrogen, Industrial, purity 99.995%

- Argon, Industrial, purity 99.995%

- Acetylene, Industrial, purity 99%

- Hydrogen, High purity (6.0), purity 99.9999%

- Nitrous Oxide, Medical, purity 99.9%

- CO2, Industrial, purity 99.9%

- CO2, Medical, purity 99.9%

BREATHING AIR PRODUCTS

- Air, Zero grade

- Heliox, Diving grade

- Oxygen, Medical, 99.5% purity

SPECIALITY GASES

- Air, 5.0 grade, 99.999% purity

- Air, 5.5 grade, 99.9995% purity

- Argon, 5.0 grade, 99.999% purity

- Argon, 5.5 grade, 99.9995% purity

- Argon, 6.0 grade, 99.9999% purity

- Helium, 5.0 grade, 99.999% purity

- Helium, 5.5 grade, 99.9995% purity

- Helium, 6.0 grade, 99.9999% purity

- Hydrogen, 5.0 grade, 99.999% purity

- Hydrogen, 5.5 grade, 99.9995% purity

- Hydrogen, 6.0 grade, 99.9999% purity

- Nitrogen, 5.0 grade, 99.999% purity

- Nitrogen, 5.5 grade, 99.9995% purity

- Nitrogen, 6.0 grade, 99.9999% purity

- Oxygen, 5.0 grade, 99.999% purity

- Oxygen, 5.5 grade, 99.9995% purity

We are capable of supplying the following refrigerant gases:

R-11, R-22, R12, R-134a, R-413, R-502, R-407C, R-408a, R-413, R-502, Isceon-69L, Isceon-59.

NIGP can supply vacuum multi-layered super insulated Dewars to ensure a low evaporation rate under prolonged use. These liquid nitrogen high performance storage vessels are available in several standard sizes from: 25, 35, 60, 65, 100, 175, 250, 300, 350 to 400 liters.

We are also capable of supplying all sizes of cylinders; 150, 200 and 300 bar, gas regulators, trolley, hoses, spindle key and all other accessories.

We are maintaining stock of manifolded cylinder quads and racks with offshore certification.

Also, different capacities of ISO Tanks, vaporizers and cryogenic hoes/rubber hoses are available on rental basis.

Dubai Oxygen Establishment

Dubai Oxygen Establishment is a leading industrial establishment, which started its production early in 1971. In response to the fast economical developments in U.A.E. in general and Dubai in particular, the production facilities were expanded to meet the ever-increasing demands for its products in the markets.

Today, Dubai Oxygen Establishment provides its customers throughout U.A.E with a wide range of products and services. Our services cover medical facilities like hospitals, clinics and health care centers besides industrial, construction and technical applications.

The motto of Dubai Oxygen Establishment was always through all these long years, High Quality Products, Better and Wider Services to our esteemed clients. Our range of products covers:

GASES DIVISION

- Liquid and Gaseous Medical Oxygen

- Liquid and Gaseous Industrial Oxygen

- Liquid and Gaseous Nitrogen

- Dissolved Acetylene

- Nitrous Oxide

- Compressed Air

- Argon

- Argon Shield

- Carbon Dioxide

- Helium

- Ammonia

- LPG

- Refrigerant Gases 11, 12, 22 and 134A

TRADING DIVISION

- Agents for U.K., Murex Welding Equipments and Consumables.

- Arc and Gas Welding Equipments and Machines.

- Workshop and Personal Safety Equipment.

Gulf Industrial Gases Company

Located in the Mussafah Industrial Area in Abu Dhabi, United Arab Emirates, Gulf Industrial Gases Co. incorporates the latest technology available from the USA.

With a production capacity of 100 metric tons per day, the plant also incorporates a hydrostatic testing facility for cylinders, which are required to be tested every three years.

Gulf Industrial Gases Co. provides much needed gases to hospitals for anesthetic purposes. Highly qualified Laboratory Technicians oversee the operations of the modern, state-of- the-art lab, ensuring all products are tested and analyzed to international standards of strength, quality and toxicity (carbon dioxide) maintaining purity of 99.995 percent at all times.

National Industrial Company

Specializing in Agricultural Irrigation Networks, National Industrial Company configures agricultural irrigation systems which optimize water distribution to roots and grasses, plants and trees.

The Company’s expert introduction of fertilizers and application of pesticides and herbicides further promotes crop growth and optimum production throughout the United Arab Emirates.

National Industrial Company also undertakes numerous green house projects including those for research and development purposes introducing the testing of new hybrid and species for tolerance, growth rate and yield.

In support of its activities, the Company imports and distributes agricultural related materials including seeds, soil, fertilizers, chemicals, pots, covers, as well as veterinary care products, medicines and public health products.

Gulf International Industrial Gases

Gulf International Industrial Gases was established in the year 2001, in Khartoum, Sudan, with a vision to meet the market requirement of industrial gases and other significant works pertinent to this field. Our products includes Oxygen (Gaseous and Liquid), Nitrogen (Gaseous and Liquid), Argon, Acetylene, High Pressure gas cylinders etc.

Our scope of service comprises of supply of Gas equipments, Central Gas systems, Hydro test service up to 600 bar and other technical support necessary for the industrial gas manufacturing field. With its dedicated work force, the company has captured the major share of the market during this short span of time.

Riyadh Oxygen Plant

Riyadh Oxygen Plant (ROP) was established in 1967 with limited production of Oxygen and Acetylene gases. As the industrial activities progressed, ROP updated the production facilities.

ROP is now one of the leading gas producers and distributors in the central region of the Kingdom of Saudi Arabia. Our new plant facilities in Industrial City No. 2 can cater to all industrial and medical gases in bulk and in cylinders.

Our transportation fleet can deliver all gases on site. ROP also offers complete cylinder testing, maintenance and related facilities.

CRYOGENIC TANKS AND EQUIPMENT

ROP can supply, install and maintain Cryogenic tanks of all sizes. All kinds of dewars for livestock, pathology blood plasma can be provided with back up supply of liquid nitrogen and other liquefied gases, vaporizers. Automatic manifold and central gas piping can also be designed and installed.

MEDICAL EQUIPMENT

ROP stocks a complete range of medical gas regulators, accessories and high-pressure cylinders

of sizes E, F and D. Complete service of valve and cylinder maintenance is available too. ROP can also undertake design and installation of hospitals, central gas piping system with air compressors, vacuum units, gas manifold, bulk oxygen storage tanks, outlet points, pendants and gas alarm systems.

CYLINDER TESTING FACILITIES

ROP has modern hydrostatic testing facilities for all high-pressure cylinders, which are required to pass a hydrostatic test periodically for sale operation. After hydrostatic testing, the cylinders meets the regulations and requirements will be stamped with dies and reused in the service of compressed gas. ROP extends these facilities to all customers using high-pressure cylinders.

GAS WELDING AND CUTTING EQUIPMENT

ROP has the most comprehensive stock of welding and cutting equipment. Gas welding and cutting sets with accessories from the popular brand i.e., victor, western, gas-arc gloor etc. are available ex-stock. A complete range of gas regulators, hoses and fittings are available. ROP also stocks rich varieties of welding electrodes, brazing rods and all kind of related flexes.

GENERAL ACTIVITIES

• All kinds of industrial and medical gases

• Refrigerant gases

• Gas mixtures and rear gases

• Cryogenic containers and dewars

• Bulk supply of liquid gases

• Gas manifolds and distribution systems

• Cryogenic storage tanks and tankers

• Medical gas central piping system and accessories

• Welding-cutting equipment and accessories

• Welding electrodes and brazing rods

• Supply of all kinds of low, medium and high pressure cylinders

• Hydrostatic testing of high-pressure cylinders

• Complete maintenance of gas cylinders

Egypt Gulf Industrial Gases Company

Established in the year 1992, Egypt Gulf Industrial Gases Co.’s quality oriented services in the field of Oil and Gas have led us to an enviable growth in this sector.

By realizing that, the products of superior quality can only survive in the market, and our dedicated work force has taken extra effort to achieve the goal which has been rewarded. We are enjoying the label of one of the best gas manufacturing companies in Egypt.

Our products range covers Liquid Nitrogen, Liquid Oxygen, Liquid Argon, Liquid CO2, Acetylene and other industrial and medical gases.

Quality specialty gases W.L.L

A new plant was commissioned in 2003. Within one year of commissioning, we obtained ISO9001 and ISO14001 certification. The plant has been constructed to produce high quality gas mixes by gravimetric techniques to customer requirements.

We can produce: -

- High purity Argon and Nitrogen:

- Carbon Dioxide n4.5

- Hydrogen up to n6.0

- Ultra pure synthetic air n5.5

- Acetylene 4.5

- Calibration gases

- Diving gases

- Medical gases

- Breathing gases

- Welding gases

- Reactive mixes

Our mixes can be divided into 2 categories: -

- % Levels up to 30 component mixes.

- Low concentration levels as low as ppb depending on customer requirements.

The plant has analytical facilities. Mixes can be analysed for any customer. We can even analyse the quality of air. All analysis results are traceable via cylinder number and computer records.

We have all cylinder sizes available in our plant, from lecture bottles, 0.4 litre,1litre up to 110 litres. All kinds of valves are available, of both National and International standard. We can also fill customer-owned cylinders.

All products are delivered to the customer for no extra charge.

Dubai Industrial Gases

DIG is a part of Al Mana Group of Companies established in Sharjah in 2004. DIG is located in Sharjah Industrial area No. 17, Sharjah University Road (Off Emirates Ring Road).

At DIG, we place great value on our relationship with our customers. We are especially proud of the reliability and diligence of our highly qualified management and technical staff.

We have a complete dedicated technology and a commitment to continuously offer new cost-effective gas supply systems and innovative applications to all our customers, through which DIG will be geared to serve its clients well into the 21st century.

Mode of supply

Our plant has a clean and safe environment. Our business is the manufacture and distribution of industrial gases including Nitrogen, Oxygen, Medical Oxygen, Argon, Carbondi-oxide, dissolved acetylene, ammonia, chlorine, Dry Ice, a broad range of specialty gases, medical gases high purity gases, gas mixtures and calibration gases. In addition, DIG supplies liquid nitrogen, oxygen, argon and C02 in vacuum insulated tanks.

Cylinder

Ultra-high purity gases of specialty gases (standard mixed-gases, chemical gases, electronic gases) are distrioc:2C by cylinders under pressure. Not only the high quality gaseous products DIG can supply the customer but Go sc DIG can supply high quality equipment related to gas cylinder.

Liquid tank

DIG supplies liquefied gases to its customer. All customer station equipments are properly selected and conformed to international standard.

DIG has the facility to provide the following packaging

• Jumbo Tubes

• Cylinder Racks

• Proven Performance.

• Vertical Storage Tanks

• Mobile Tankers

All these services are made available to our valued customers through a team of qualified sales and marketing professionals that adhere to the strictest of professional and ethical standards.

Al Khor Factory

Al Khor Factory for Timber Products is a member of M.H AL Mana group of Companies located at New Industrial Area. AKF is inline of Manufacturing of Fire Rated and Non-Fire Rated Wooden Doors, Furniture, Kitchen Cabinets & Kitchen projects.

Al Khor Factory is a reliable Fire Rated Door manufacturer in Qatar by using high quality materials while applying the latest technology and machineries, plus having a certified certificate fromIFC Certification and Qatar Civil Defense respectively.

Our duty is to exceed our client’s expectations through quality work, materials used and a satisfying experience with high quality products and services at a competitive price .